- SUNBEAM MOTORCYCLES. HEADER PAGE.

- SUNBEAM NEWS and START PAGE

- About the bike.

- Distributor Internals

- Redundant spark ignition.

- Coil Information.

- Beam-Spark Ignition Unit

- FOR SALE

- Smiths Chronometric Speedometer

- Calibrating Smiths Chronometric Speedometer.

- Speedometer Drives.

- Companies and Products.

- My other bikes.

- The Horn. and Rear Brake Spring.

- HOW TO PAGE

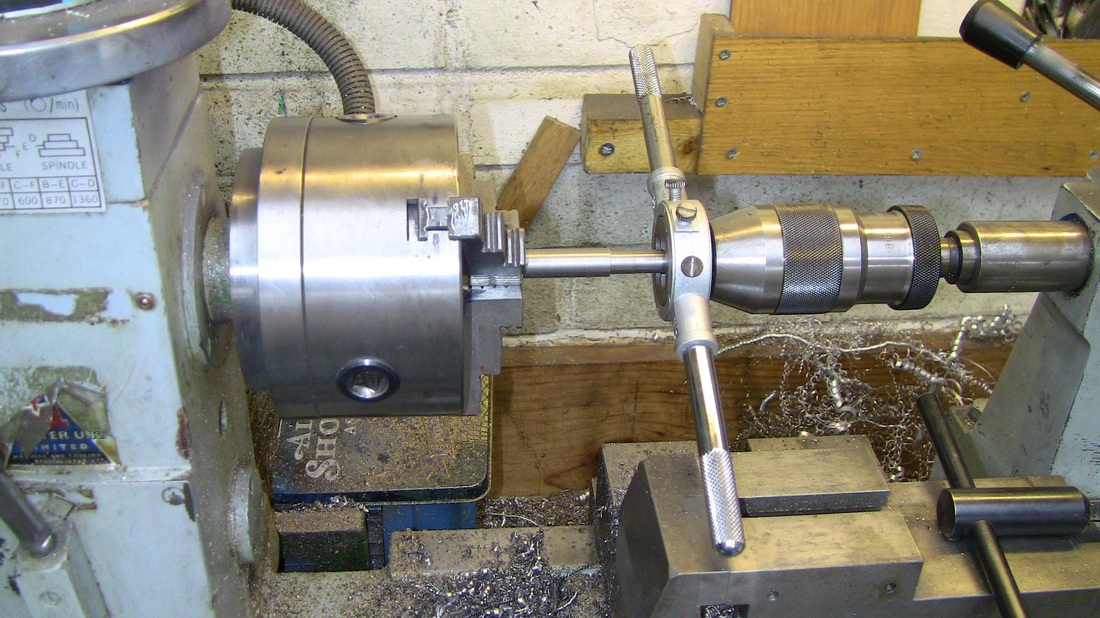

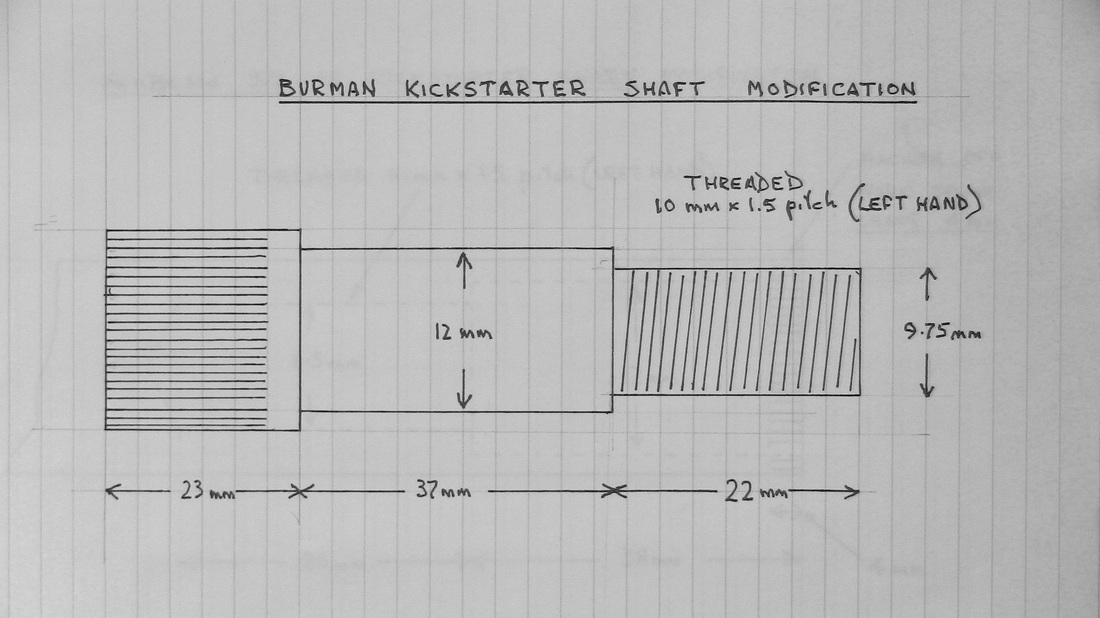

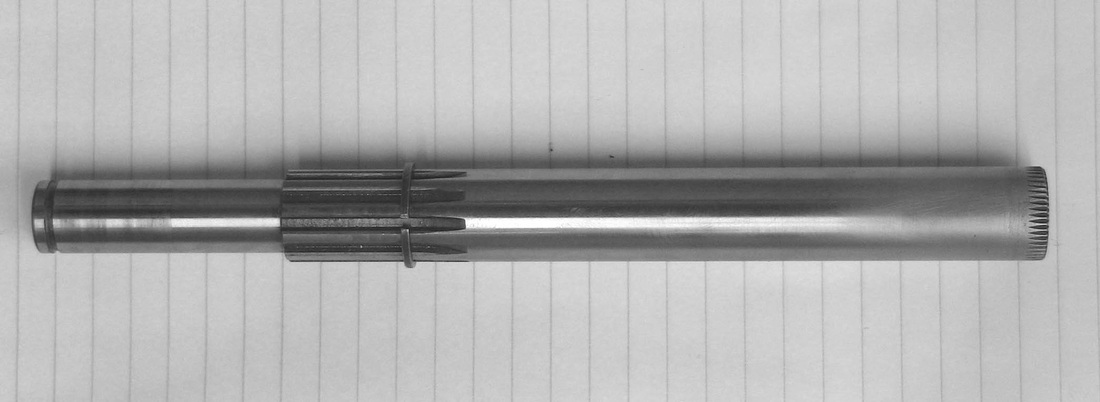

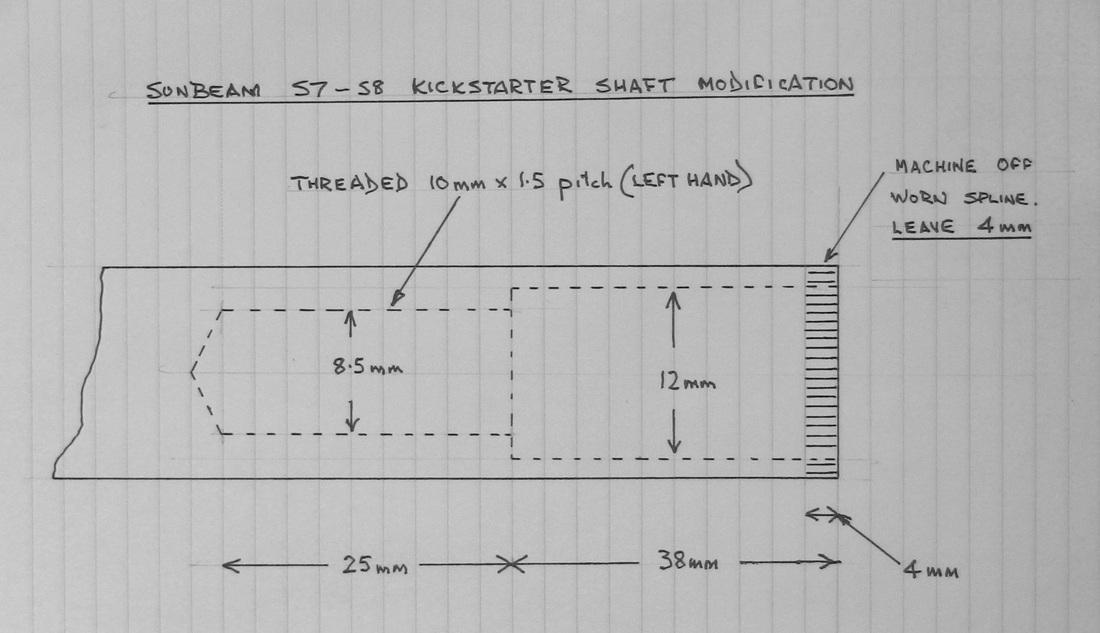

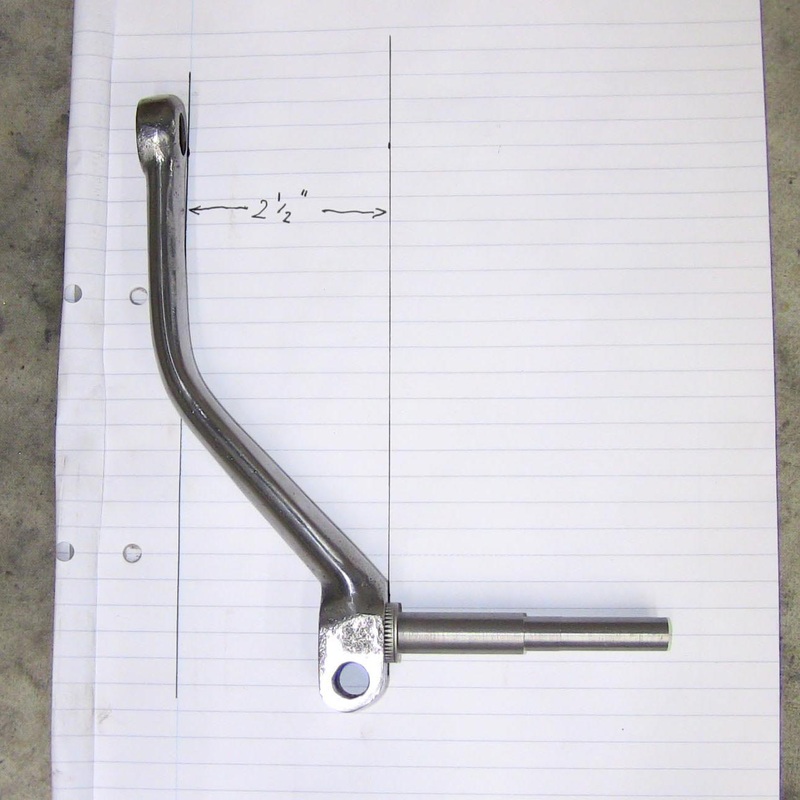

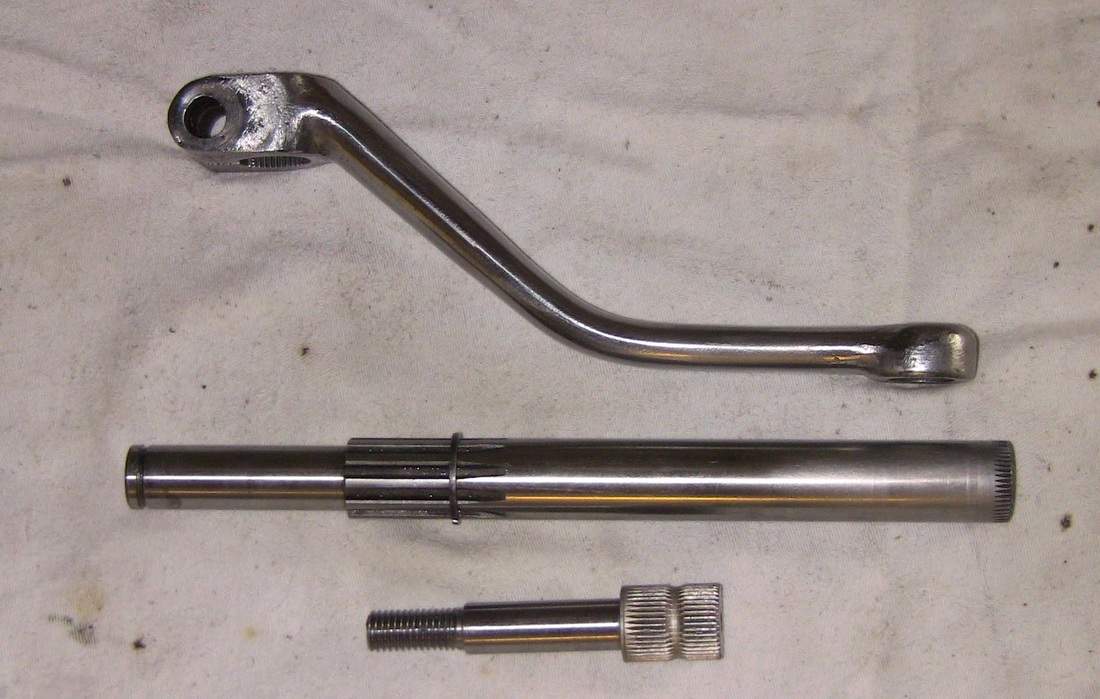

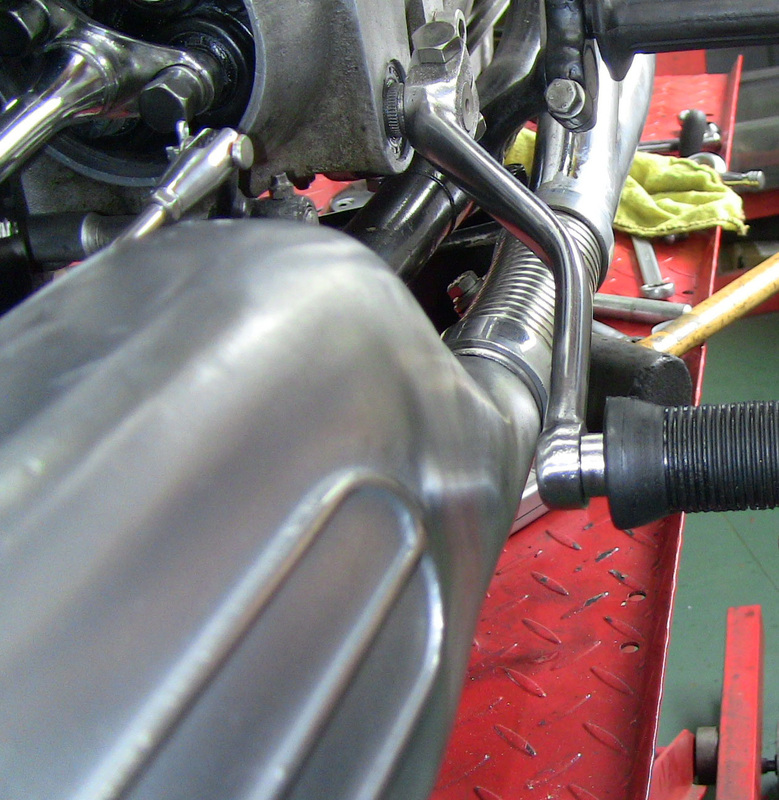

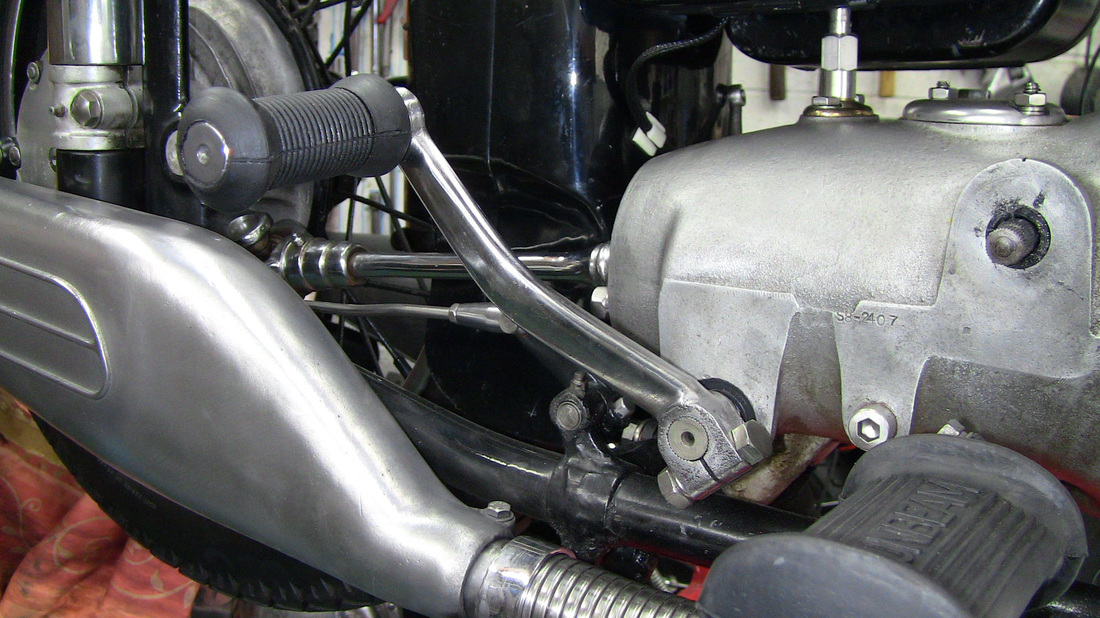

- Modifications Page One

- Modifications Page Two

- Modifications Page Three

- Dipsticks,sumps and oil weirs.

- The Electrics

- Sunbeam Dynamo in depth.

- Repairs and Maintenance.

- Carburettors

- S8 Front forks.

- Full width front brake on the S8.

- Top dead centre.

- Your Sunbeam.

- All things wheels.

- Data Sheets.

- Engine breathing and oil leaks.

- Putting the engine together.

- Stainless Steel Exhaust

- Tools

- All things final drive

- I80 Degree Crankshaft

- Completed engine speed ignition sytem.