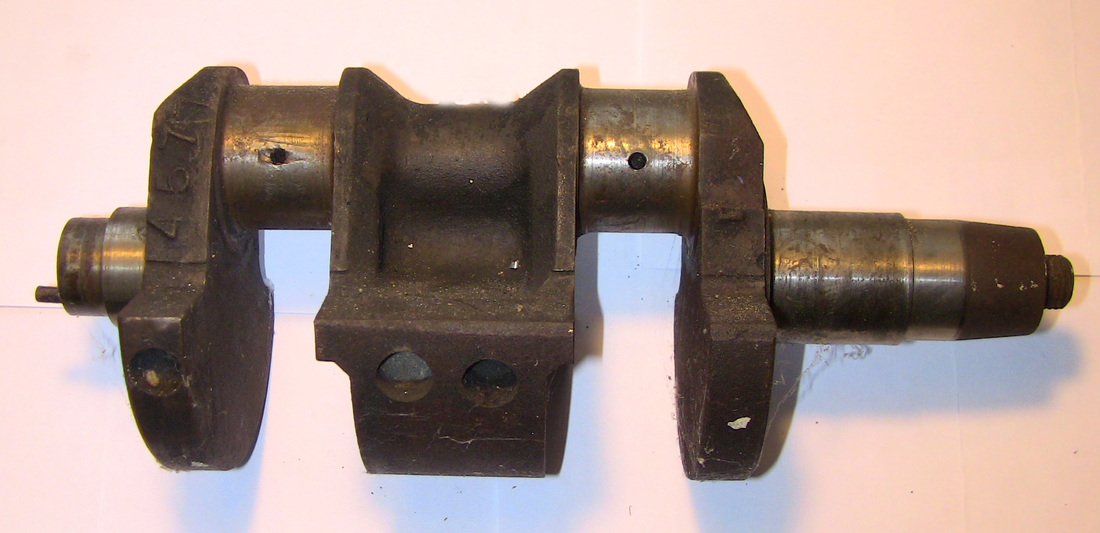

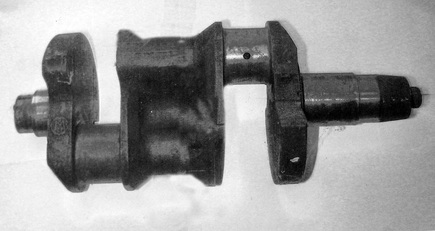

180 Degree Crankshaft.

Due to ill health and the loss of my partner on this scheme this project is now abandoned.

This crankshaft arrangement has a number of disavantages. It is inherently out of balance being the main drawback. The pistons rising and falling together are in effect an air compressor and cause problems with air and oil being blown out of the engine especially at high revolutions.

Now if the cranks could be arranged at 180 degrees to one another this would improve the mechanical balancing and reduce the air pump effect. However, on a two cylinder 180 degree crank engine another force is introduced called a rocking couple. This can be observed on a bicycle where the alternate forces on the pedals cause the frame of the bicycle to rock or rotate around the centre line of the bike.

This force is minimized where the crankshaft is in line with the frame as is the case with the Sunbeam engine. The remaining problem is the ignition of the individual cylinders which is now non symmetrical.

The modern day ignition systems can overcome these problems relatively easily with built in electronic advance and retard. Ignition pickup could be either from the camshaft or directly from the flywheel rim magnetically or optically.

I have now approached a small engineering company who are to make an 180 degree crankshaft for me. This is to be manufactured in one piece on a CNC machine. The machining is straight forward and when the technical aspects are sorted out the crankshaft will come into existence sometime in 2016.

If anyone has any ideas regarding 180 degree crankshafts please contact me at [email protected]

Has a 180 degree Sunbeam crank been proposed in the past ?

Now if the cranks could be arranged at 180 degrees to one another this would improve the mechanical balancing and reduce the air pump effect. However, on a two cylinder 180 degree crank engine another force is introduced called a rocking couple. This can be observed on a bicycle where the alternate forces on the pedals cause the frame of the bicycle to rock or rotate around the centre line of the bike.

This force is minimized where the crankshaft is in line with the frame as is the case with the Sunbeam engine. The remaining problem is the ignition of the individual cylinders which is now non symmetrical.

The modern day ignition systems can overcome these problems relatively easily with built in electronic advance and retard. Ignition pickup could be either from the camshaft or directly from the flywheel rim magnetically or optically.

I have now approached a small engineering company who are to make an 180 degree crankshaft for me. This is to be manufactured in one piece on a CNC machine. The machining is straight forward and when the technical aspects are sorted out the crankshaft will come into existence sometime in 2016.

If anyone has any ideas regarding 180 degree crankshafts please contact me at [email protected]

Has a 180 degree Sunbeam crank been proposed in the past ?