Engine breathing and oil leaks.

Problem with 360 crank twin cylinder engines is they are a natural air pump. Any ideas for to improve breathing without blowing out oil or oil mist I am sure will be welcome. Timed breathing is a requirement on this type of engine, in other words the air is blown out of the crankcase on the downward stroke of the two pistons through the disc valves in the cam cover. On the upward stroke the valves are closed through suction and the crankcase will be at negative pressure. I found that on a long run from Calais to Normandy at 60 mph that the twin breather with pipes shown in the photos remained oil free. I also found with the experimental long nuts holding the cambox cover on that the cambox had condensation in it so that the cambox was overcooled. This led me to think there must be a considerable cooling air flow over the camcover at speed. I also think the fuel tank tunnel adds to this air stream. So I discarded the plastic pipes and have fitted tee pieces to the breather stubs. This idea is based on the venturi principle so that at speed the air in the cambox is 'sucked'out therefore reducing back pressure...........We shall see !

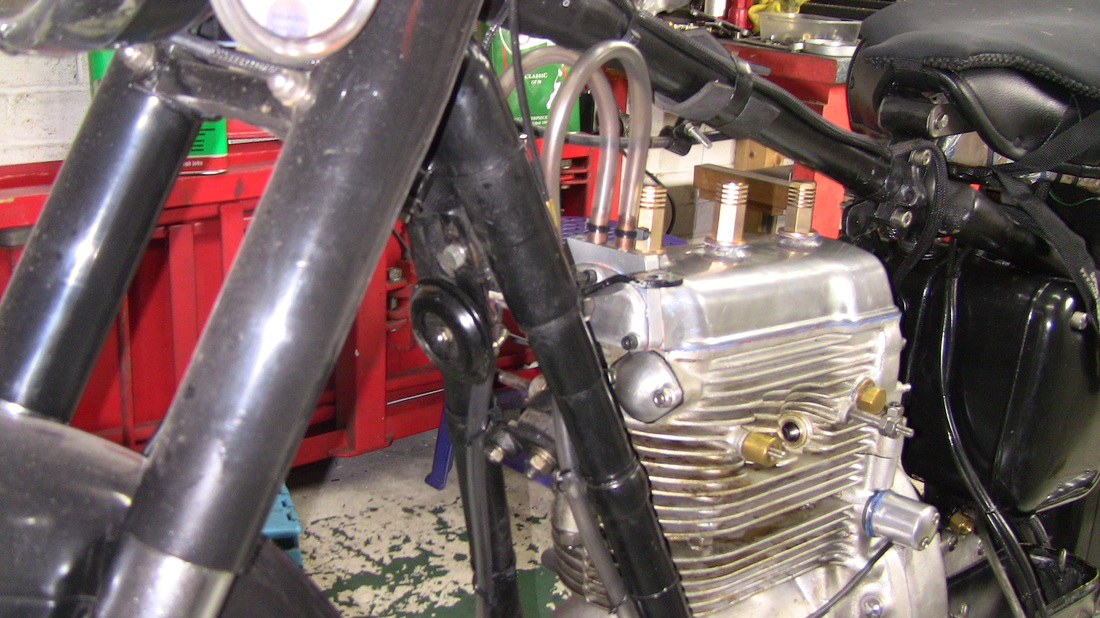

First breather with plastic pipes.

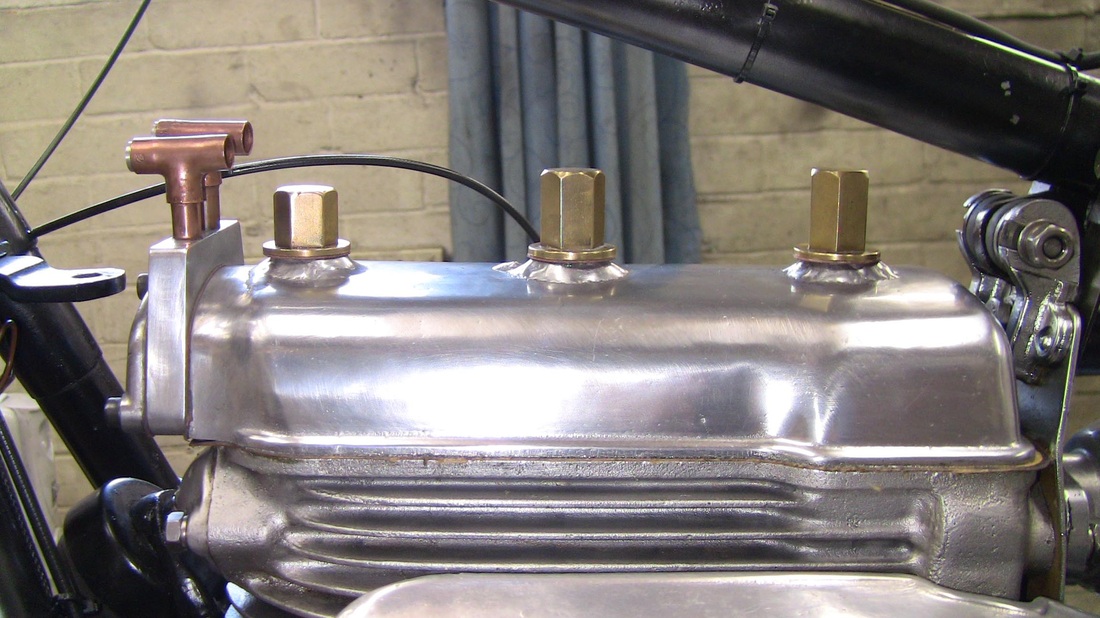

Home made breather assembly.

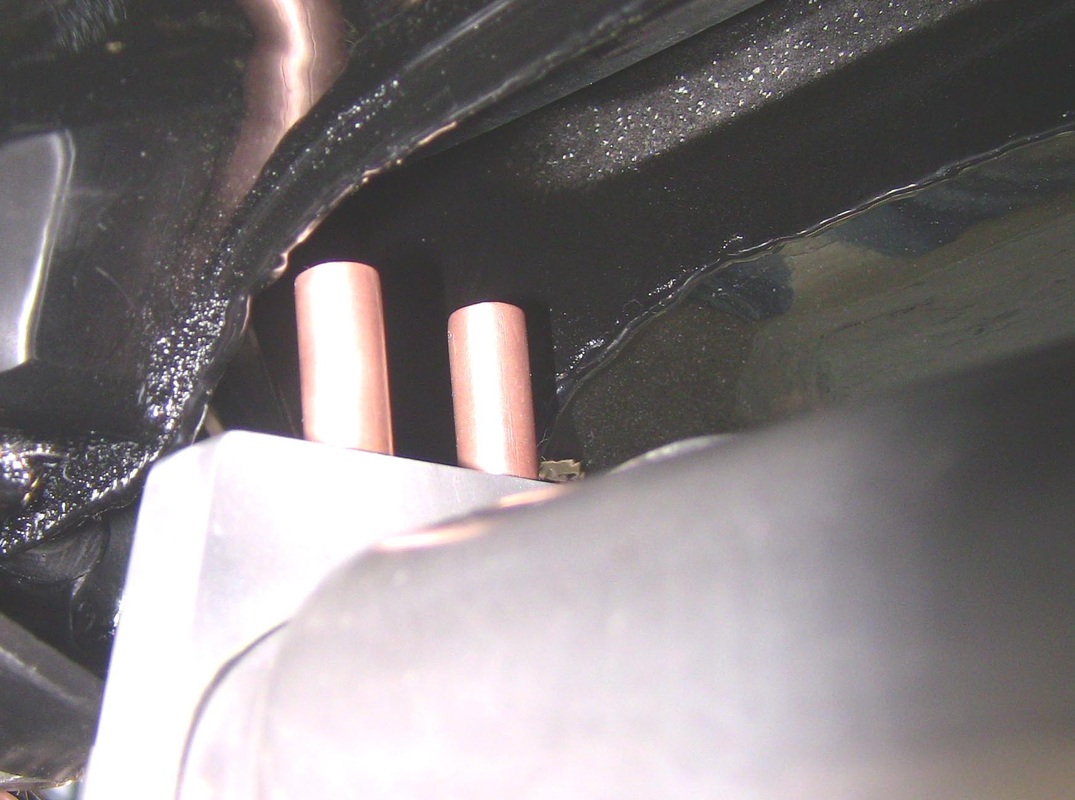

Checking the clearance under the fuel tank.

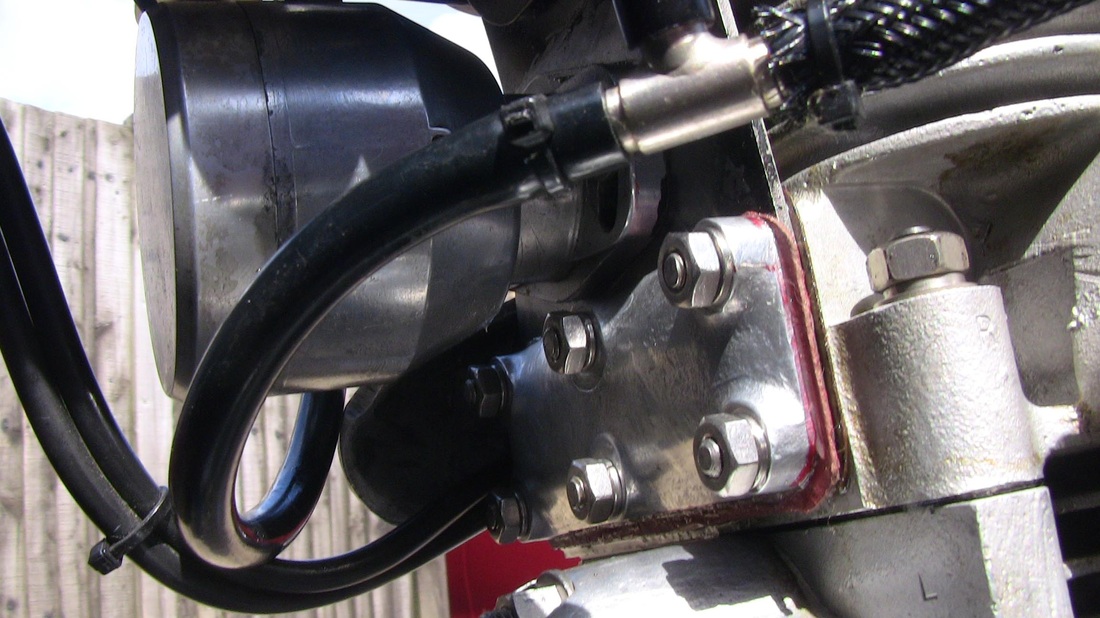

The lowest nut behind the breather pipes so air flow through venturis is smooth.